|

|

|

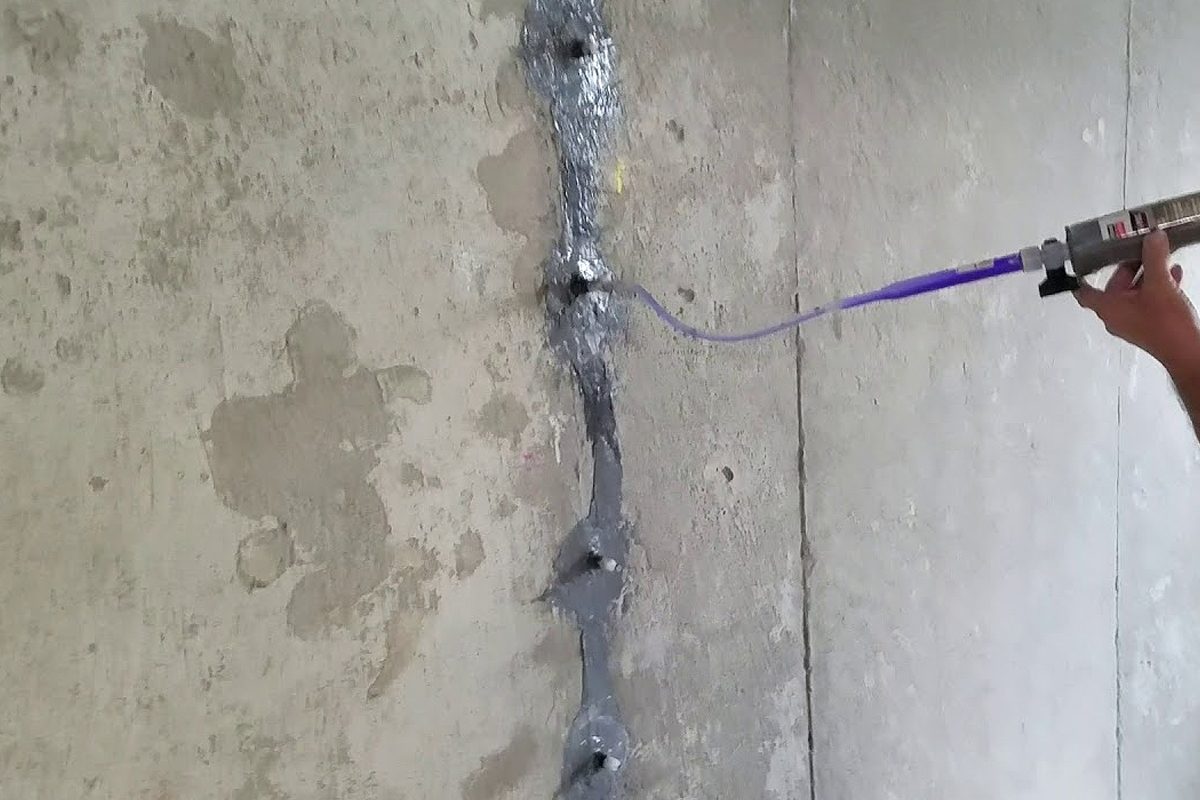

| Injection of cracks in overhead concrete slab | Injection of expansion joint between overlapping concrete slabs |

Concrete injection has been in use worldwide for several decades and is arguably the most common concrete crack repair method used for underground poured concrete structures and underground waterstopping in general. The two images above are typical commercial applications of concrete injection using polyurethane, also referred to as urethane, resins.

Injection of Cracks in Poured Concrete

The image on the left is of a polyurethane injection of a poured concrete ceiling slab crack in a meat processing plant in Burlington, Ontario. Pressurized injection of polyurethane was required in order to repair the leaking cracks in the ceiling which were preventing the construction of a processing line below. The concrete cracks in the overhead slab leaked substantial amounts of water due to the daily powerwashing of another processing area located on the level immediately above.

Concrete Injection for Expansion Joints

The image on the right shows a polyurethane injection of an expansion joint between two overlapping concrete slabs in the underground parking garage of a high-rise condominium building in Toronto. The lower slab is actually a wide concrete structure supporting the floor slab of the parking level above. The leak to be repaired was caused by ground water travelling between the two poured concrete structures. The precise origin of this water could not be determined given the size and construction of the large multi-level parking garage, therefore, concrete injection with polyurethane was the only viable means of stopping the water from leaking onto a vehicle parked directly beneath the joint.

Note: Concrete injection is not strictly accomplished using polyurethane; epoxy crack injection is another method of concrete injection, specifically for concrete crack repair.

Polyurethane Concrete Injection Video

Checkout this one minute video showing the process of injecting a concrete crack using polyurethane.

Concrete injection using polyurethane is in many cases the only option for waterstopping of underground poured concrete structures such as basement walls, parking garage walls and ceilings, and structures such as underground storage tanks and cable rooms.

Polyurethane crack and expansion joint injection is in common use because of the attributes of the polyurethane resin. There are several attributes that make concrete injection using polyurethane highly useful and desirable:

- Polyurethane expands significantly after it is injected; as a result, it will find and fill any gaps and voids where water is passing through and causing problems;

- Polyurethane can be used in both wet and dry applications;

- Concrete injection is much less expensive than excavation; and

- Concrete injection, when done properly, is very effective and reliable in waterstopping applications as it can withstand significant hydrostatic pressure.

Click on this link for a comparison of the epoxy and polyurethane crack injection methods.